FAST SHIPPING & FACTORY DIRECT SUPPORT

- Home

- Floor Machines

- Pad Drivers

ABOUT PAD DRIVERS

When adding a pad driver to your floor machine there are two main options to choose from - a Tufted Pad Driver or a Polymeric Pad Driver.

The main difference is how the pad drivers hold onto the pad. A Tufted Pad Driver usings heavy 1/2" long polypropylene bristles to secure the pad. The Polymeric Pad Driver uses small hooks to grasp the floor pad.

Either option holds the floor pad to the driver and floor machine as well as the other. A Tufted Pad Driver is generally more durable since it is constructed from thicker material and allows for replaceable parts if something breaks. The Polymeric Pad Driver is usually the more economical choice.

Visit our Pad Driver 101 page to learn more about the function of a pad driver.

Recommended: Choose a pad driver with a 1 1/4" riser that is the same size as your floor machine diameter to maximize your cleaning. If you select a pad driver without a riser choose one 1" smaller than your floor machine.

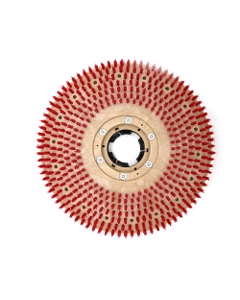

TUFTED PAD DRIVERS

Powr-Flite tufted pad drivers all include 1/2" long heavy polypropylene bristles with 1/2" staple set for secure pad holding and includes a 1 1/4" riser. Each have replaceable clutch plates and risers.

POLYMERIC PAD DRIVERS WITH 1 1/4" RISERS

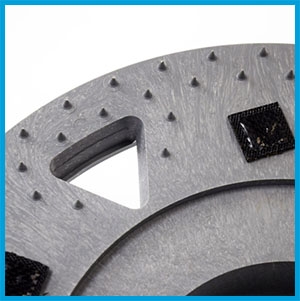

Powr-Flite polymeric pad drivers are one-piece heavy duty molded pad drivers with built in 1 1/4" risers and replaceable clutch plates.

POLYMERIC PAD DRIVERS WITHOUT RISERS

Includes holes for a shower-feed system allowing it to be used with solution dispensing machines.

SANDING PAD DRIVERS